-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

August 28, 2019

What Is Physics of Failure?

Engineers know that product performance and reliability are vital to defense applications. As a result, defense engineers were some of the first to embrace the field of reliability engineering.

When reliability engineering started it focused on metal fatigue and fracture. As these design for reliability (DfR) strategies improved, they spurred a shift to electronics reliability using prediction, simulation and testing tools.

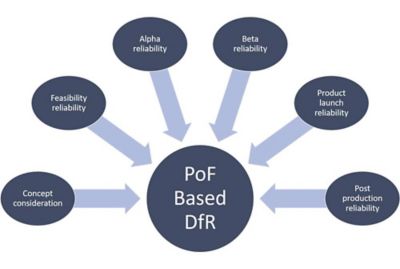

Physics of failure (PoF) based on design for reliability (DfR)

improves concept, feasibility, alpha, beta, launch and production reliability.

This DfR methodology served as the basis for the physics of failure (PoF) approach that is common in many industries today.

What is Physics of Failure?

Physics of Failure is a scientific discipline that determines the root causes of failure for electrical, electronic or electromechanical (EEE) items. These items can include:

- Piece parts

- Sub-assemblies

- Modules

- Equipment

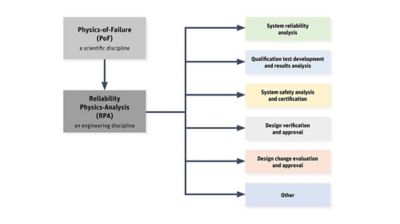

The relationship between PoF and RPA

Physics of Failure is used to understand how physical chemical, mechanical, thermal or electrical stresses can degrade or cause the failure of electrical, electronics or electrictromechanical items. The scientific discipline also provides algorithms to estimate the likelihood of failure within specified environments. PoF aligns design, electrical and mechanical engineering functions early in the development cycle.

PoF research has evolved into reliability physics analysis (RPA), also known as the PoF engineering approach. RPA is an engineering discipline that implements the principles of PoF within specific applications.

RPA employs constitutive and numerical PoF models to estimate the likelihood of failure of EEE items over time and under defined conditions. Therefore, engineers can use RPA to optimize the performance, reliability and durability of EEE items. RPA applies “cause and effect” relationships to failure mechanisms and the variable factors that make failures appear to be random events.

The Future of Physics of Failure

Smaller, faster and more complex electronics are popping up in various industries, including automotive, defense, healthcare and consumer products. The inclusion of these electronics is driven by various trends including:

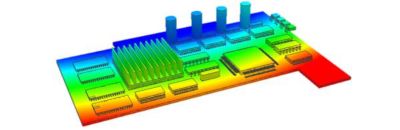

A mechanical shock simulation from Ansys Sherlock

A lot of the hardware associated with these trends have never lived outside a datacenter, office or home. However, they are now being added to products that require reliability standards far beyond what is currently expected.

For example, current automotive electronic modules are typically designed and validated for 5,000 to 9,000 operating hours over a lifespan of 10 to 15 years. However, upcoming autonomous taxis are expected to operate 22 to 24 hours a day over 4 to 6 years. That means that the semiconductors and electronic modules powering these autonomous vehicles will be expected to operate 32,000 to 53,000 hours under conditions that exceed current industry expectations and validations requirements. To determine the electronic reliability of these products in these new environments, engineers will need to use PoF techniques.

Additionally, the supply chain for electronics can be complicated. There can be four to six suppliers between the person concerned about reliability and the company actually making the part. Each of these parts can have half a dozen failure mechanisms and a board can have thousands of parts. PoF is essential to understand these failure mechanisms and how they are affected by the environment the product operates within.

How Ansys Sherlock Assists the PoF Discipline

Historically, PoF requires engineers to gather over 50,000 pieces of data and perform 10,000 different calculations. This obviously required an enormous amount of time. With the introduction of Ansys Sherlock, however, engineers can perform reliability physics analysis within minutes. This analysis can identify failure mechanisms on the components, board and system.

Sherlock provides engineers with a turnkey solution to develop physics-based reliability predictions for each of their parts. Engineers can then optimize the parts for their intended operating environment. Sherlock complements and leverages the knowledge engineers can learn from materials properties, modeling and simulation.

Sherlock can accurately predict failure behavior for next generation:

- Silicon transistors

- Wire bonds

- Solder bumps

- Die attachments

- Light emitting diodes (LEDs)

- Electrolytic capacitors

- Plated through holes (PTHs)

- Solder joints

For a deeper dive into PoF and product reliability, watch Introduction to Reliability Physics Analysis.

Or attend the first of our three-part webinar series on Automotive Electronics Reliability:

Part 1: Meeting Automotive OEM Specs with Virtual Validation

See What Ansys Can Do For You

See What Ansys Can Do For You

Contact us today

Thank you for reaching out!

We’re here to answer your questions and look forward to speaking with you. A member of our Ansys sales team will contact you shortly.